How Sticky is the Self Adhesive PVC Film?

How Sticky is the Self Adhesive PVC Film?

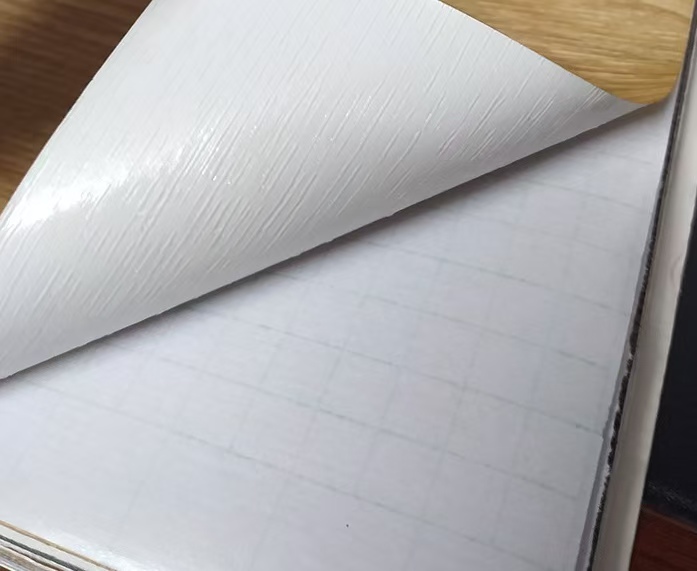

The stickiness or adhesion of self-adhesive PVC film is its main function, which is designed to provide fast, convenient, and reliable adhesion. The strength and durability of the adhesion will vary according to different manufacturing standards and application requirements, in addition to time, environment, and application surface.

Adhesion level

The adhesion of self-adhesive PVC film ranges from very low (only slightly sticky) to very high (strongly sticky and difficult to remove). PVC film manufacturers usually provide products with different adhesion levels to meet different application requirements:

- Low adhesion (light adhesion): Its adhesion is very low, making the PVC film easy to tear off and remove. This PVC film is suitable for temporary identification, labels, or signs that need to be used temporarily in interior decoration or promotional activities, with low adhesion requirements and high requirements for easy removal and no residual adhesive on the surface of the object to be pasted.

- Medium adhesion (standard adhesion): This PVC film has stable adhesion performance and is compatible with application surfaces made of various materials. It can resist the wear and tear caused by daily use. Therefore, it is very suitable for indoor long-term use applications, such as desks, office desks, cabinets, etc. These applications are indoors, not often exposed to sunlight, and the temperature range of the environment is not extreme. Medium-viscosity PVC film is sufficient to meet the adhesion requirements of these applications.

- High viscosity (strong adhesion): High viscosity has better resistance to UV rays and extreme temperatures, and can maintain long-term adhesion under extreme climate conditions, making the PVC film not easy to fall off. Therefore, it is suitable for long-term outdoor applications, such as billboards, car decorations, building signs, etc.

- Repositionable (removable and repositionable): It has high viscoelasticity, which means that it maintains a balance between viscosity (making objects stick) and elasticity (the ability of the material to rebound). This balance allows it to be repeatedly torn off and pasted. When it is torn off, there will be no residual glue, and when it is pasted again, the adhesion is still very good. This PVC film is very suitable for applications that need to be frequently moved or adjusted, such as temporary exhibitions, seasonal promotions, and event signage.

- Ultra-high viscosity (super strong adhesion): It has the highest viscosity and provides an almost permanent bond, making it stable even under high loads or frequent contact, which is very suitable for applications that require extremely high durability. Such as heavy machinery, industrial equipment identification, or ground identification in high-frequency wear areas.

Environment

PVC films with the same viscosity will show different viscosity in different environments. For example, a medium-viscous PVC film will show better viscosity in a normal indoor temperature environment and an outdoor environment with strong sunlight for the same period. This is because temperature changes, humidity, UV exposure, and other environments will affect the viscosity of the film.

Application surface

The viscosity of the PVC film also depends on the type of surface to which it is pasted. Smooth, dry, and clean surfaces usually provide the best adhesion effect, because dry and clean surfaces help reduce the effects of air and water vapor on viscosity. Smooth surfaces make the film adhere better, thereby increasing the viscosity of the film.

On the contrary, rough, porous, or oily/wet application surfaces may reduce the adhesion effect for the following reasons:

- Rough/porous application surfaces: It is easy to leave gaps between the PVC film and the application surface, reducing the contact area between the film’s adhesive and the application surface, thereby reducing the viscosity of the film. The gaps are prone to residual air, which makes it difficult for the film to fit tightly with the application surface, which also reduces the viscosity of the film.

- Application surface is oily/wet: The surface is oily or wet, which is equivalent to the presence of other substances between the PVC film and the application surface, especially oil, which has a lubricating effect. This has a great impact on the viscosity of the film, making it difficult for the adhesive to contact the application surface. Wetting will retain a lot of water between the film and the application surface, and the water will dilute the adhesive of the film, thereby reducing the viscosity of the film.

Time

When the self-adhesive PVC film is just pasted on the application surface, the viscosity is not high. At this time, the film is just pasted on the surface and the adhesion is still slowly working. After a period of pasting, the film’s adhesion ability is the greatest. After that, as time goes by, the viscosity will slowly decrease due to environmental influences.