How to Prevent PVC Film from Bubbling?

How to Prevent PVC Film from Bubbling?

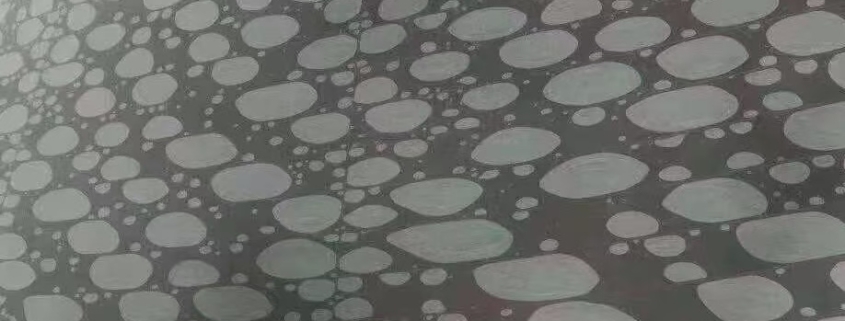

PVC film bubbling is a common problem, especially in environments prone to bubbles, such as high temperature and humidity. Bubbling is usually caused by the accumulation of air, moisture, or other gases between the film and the attached surface. There are many reasons for air retention, in addition to the environment, there is also residual dust on the application surface, improper operation process, etc. Therefore, preventing PVC film bubbling can be started from two aspects: operation and material.

Materials

- Thick PVC film: Thick PVC film is usually less likely to bubble. First, it is more resistant to the pressure of bubbles. Second, thick films are easier to squeeze out air during operation and are less likely to remain in the film.

- PVC film with microporous technology: Some PVC films use microporous technology, which allows air and water vapor to pass through. Because its tiny holes provide channels, the air and moisture below can escape through these micropores instead of accumulating under the film to form bubbles and condense water vapor.

- Pre-coated PVC film: Pre-coated PVC film has been evenly coated with a layer of adhesive. This industrial-grade gluing method is more uniform than manual gluing, which can effectively avoid the bubble problem caused by uneven gluing and make the application process faster and easier. In the production process of pre-coated PVC film, the precise machinery and equipment used to control the pressure of gluing and laminating help to completely expel the air between the film and the adhesive layer.

Operation

During the operation process, paying attention to various aspects of the operation can also reduce the generation of bubbles in the PVC film, such as cleaning the application surface, compacting the PVC film, expelling air, etc.

- Control environmental conditions: It is well known that a good environment helps PVC film to be installed and applied better. Choosing a dry, cool, room temperature, and dust-free environment can effectively avoid the impact of environmental factors such as humidity and high temperature on the PVC film, thereby reducing the air and water vapor left between the PVC film and the application surface.

- Fully prepare the substrate surface: Before applying the PVC film, the substrate surface should be clean, flat, dust-free, and oil-free. You can first use a cleaning tool to clean the surface of the application surface to remove dust, fine particles, stains, etc. If there are solid stains, you can use sandpaper to polish the surface to remove stubborn obstacles. Finally, use a detergent to further clean the application surface. After the application surface is dry, operate again to reduce the air and water vapor between the application surface and the film.

- Use appropriate adhesives: High-quality adhesives compatible with PVC films make it less likely for water vapor and air to penetrate the film. When applying the adhesive, try to apply it evenly. Uneven adhesives are also prone to residual air, causing blistering of the PVC film.

- Expel air: When applying PVC film, use a roller or similar tool to push evenly from the center outward to expel the air below. It is best not to use your hands to push because the surface of a person’s hand is not flat, it is uneven, and using your hands to push, firstly, the non-screen surface makes it easy to squeeze out the air incompletely. Secondly, the pressure of a person’s hand depends on the person, and the force is unbalanced, it may be strong here and weak there, which is easy to leave the air. The force of the roller tool is strong and uniform, and the force is the same everywhere.

- Post-processing: After the operation is completed, if you are still worried that the air between the film and the application surface has not been eliminated, you can process the PVC film later to expel the air between the film and the application again. Usually, a hot air gun is used to gently heat the surface of the PVC film, which helps the adhesive to cure better and escape small bubbles.